Soundlag NL-GW

acoustic pipe lagging - fire retardant noise barrier with glass wool backing

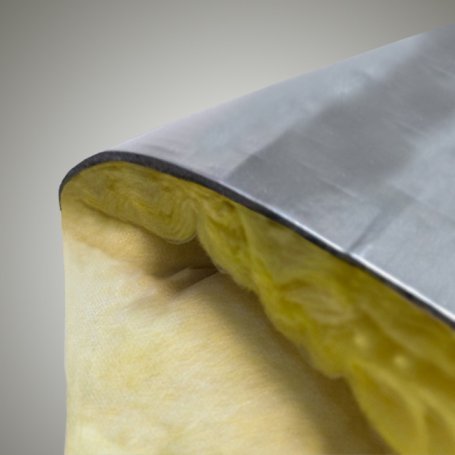

Soundlag NL-GW is a high-performance composite acoustic lagging product consisting of an aluminium foil-faced, mass-loaded, flexible vinyl noise barrier laminated to a glass- wool decoupling layer. The product was developed to reduce noise break-out from pipes, valves, fan housings and ductwork in commercial, industrial and domestic buildings.

The unique construction of Soundlag™ NL-GW combines the superior transmission loss performance of the noise barrier, Wavebar®, with the high absorption properties of the decoupling glass-wool layer Sorberglass.

The decoupling layer breaks the vibrational path between the decoupled mass barrier and the substrate to which it is bonded. This allows the vinyl external wrap to remain flexible at all times, thereby optimising its performance. The tough external aluminium foil facing provides good mechanical protection from dirt, oil and dust and offers a fire resistant covering.

The external barrier wrap, Nonlite (NL), is highly fire retardant with enhanced self-extinguishing properties and low smoke and toxicity characteristics. The decoupling layer is a lightweight 25 mm thick, non-combustible, glass wool (GW).

Soundlag products are easily cut to size with a knife or scissors and installed in 3 easy steps: cut, wrap and tape; making it the most cost effective acoustic lagging product on the market.

Soundlag products contain no ozone-depleting substances and comply with European and Australian standards for Volatile Organic Compound emissions.

Technical data

Soundlag NL-GW is a high-performance composite acoustic lagging product consisting of an aluminium foil-faced, mass-loaded, flexible vinyl noise barrier laminated to a glass- wool decoupling layer.

Please refer to the Technical Data Sheet (TDS) for more information.

Applications

- Hydraulic and waste pipes in all locations

- Air-conditioning ducting and shrouds

- Compressor wraps

- Spa motor wraps

- Factory custom cut sizes available or can be cut to size easily with a knife on site

- Working with acoustic consultants and test facilities, Pyrotek has designed and tested systems that achieve a high level of noise reduction for all plumbing and hydraulic situations

Features

- Heat and light reflective facing

- Ignition retardant barrier layer

- Low cost and long-lasting

- No ozone-depleting substances generated during manufacture

- This product is classed as low VOC emitting material

- Free from odour-producing oils and bitumen

- Reduces the noise in hydraulic and waste pipes by up to 20.5 dB(A)

- Broad operating temperature range

- Tested to international standards for fire properties

- Low spread of flame surface

- Easy to install

- Made in Australia – accredited to ISO 9001 Quality Control Standard

- Endorsed and tested by leading acoustic consultants and engineers combined with independent lab and field testing

- Available in various barrier weights

- Glass-wool decoupling layer can be quilted with a fabric covering on request (Refer information page 441IP)

- Easy to bond onto other substrates using matching Tape ALR adhesive or equivalent